Optimize Your CNC Parts with the INSTAPART Design Guide

Reduce costs and improve efficiency with our expert cnc guidelines.

GET INSTANT QUOTE

Reduce costs and improve efficiency with our expert cnc guidelines.

GET INSTANT QUOTE

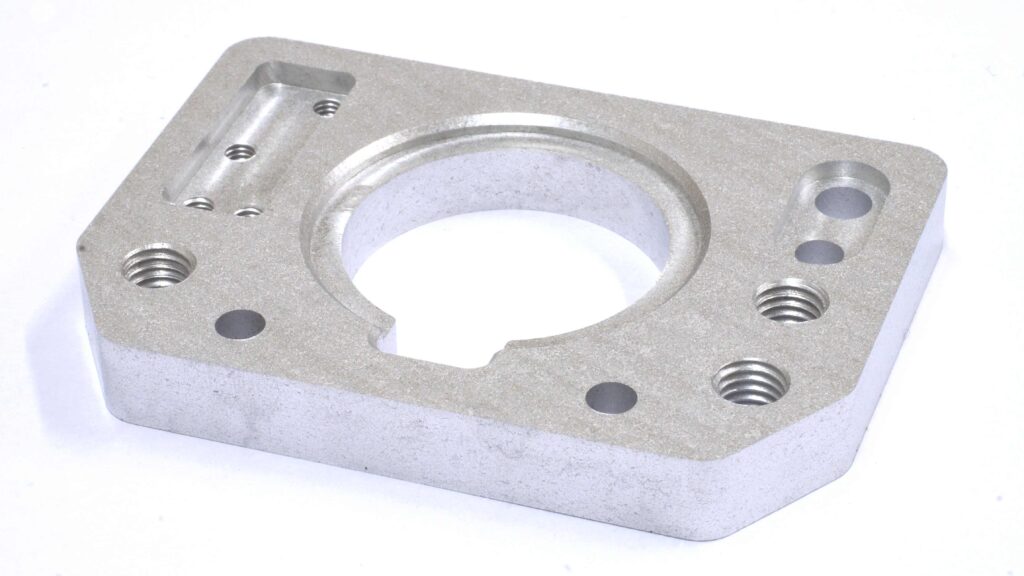

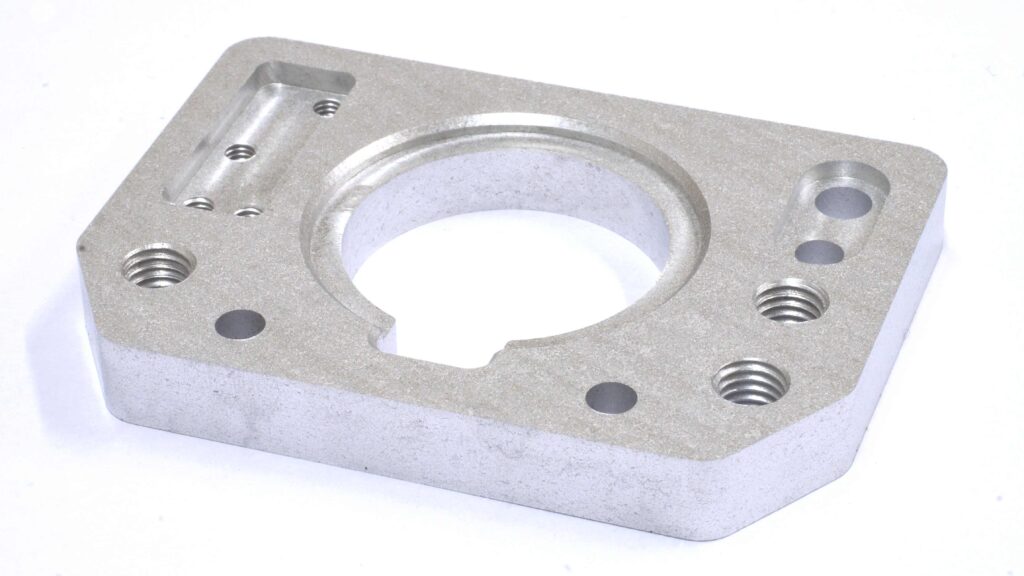

The design tips from INSTAPART are here to help you optimize 2D CNC-milled parts, saving time and money. By following these guidelines, you can reduce manufacturing time and costs while ensuring high-quality results. Whether for prototypes or small production runs, these tips make your parts more efficient and cost-effective.

To achieve the most cost-effective manufacturing process, consider the following tips:

These are the most cost-effective option as they can be milled in bulk in a single setup.

We recommend keeping internal radii as large as possible and maintaining part thickness

according to our raw material sheets. This approach reduces both milling time and costs.

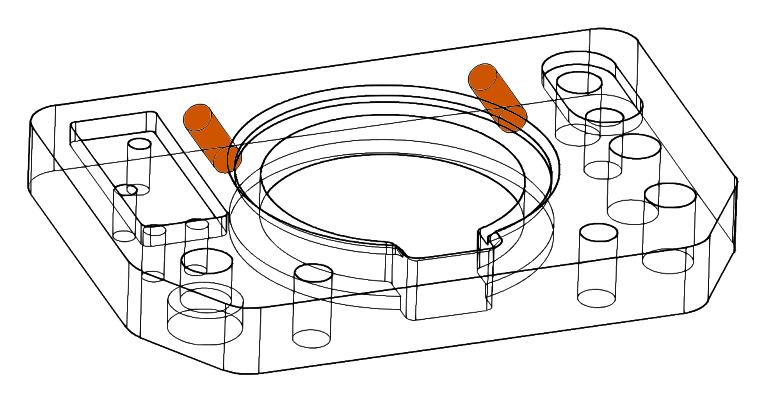

Manufacturing these parts is more complex and slightly more expensive. Note that we can only mill

internal 2.5D features, such as pockets, holes, and threads, from the backside.

We can add side bores, precise fits, or threads, typically costing around 2-5€ per piece.

To keep costs down, ensure these features are easily accessible and within our standard range of drills,

threads, and precise fits.

We can only mill parts larger than 20 x 20 mm due to workholding constraints. For smaller parts, use our downloadable support frame to place your part within the tab structure. We will ship the complete part with tabs attached.

Our software will automatically check if your part fits within our dimension criteria.

INSTApart manufactures parts up to 950 x 450 x 20 mm.

INSTApart aims for high precision, but slight deviations from CAD models are inevitable.

We typically achieve ±0.05 mm per 100 mm, meaning a 100 mm part ranges from 99.95 to 100.05 mm. Currently, we guarantee ±0.1 mm per 100 mm at room temperature.

For precise fits, we provide an optional H9 tolerance. Although we strive for H7 accuracy, we guarantee H9.

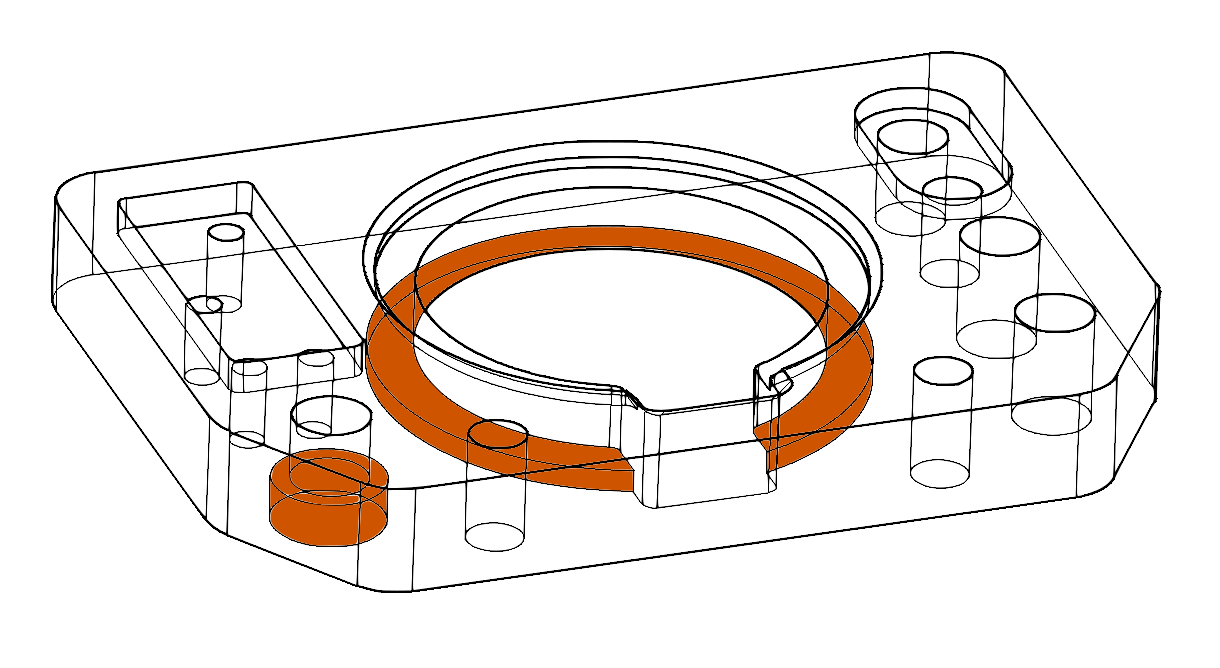

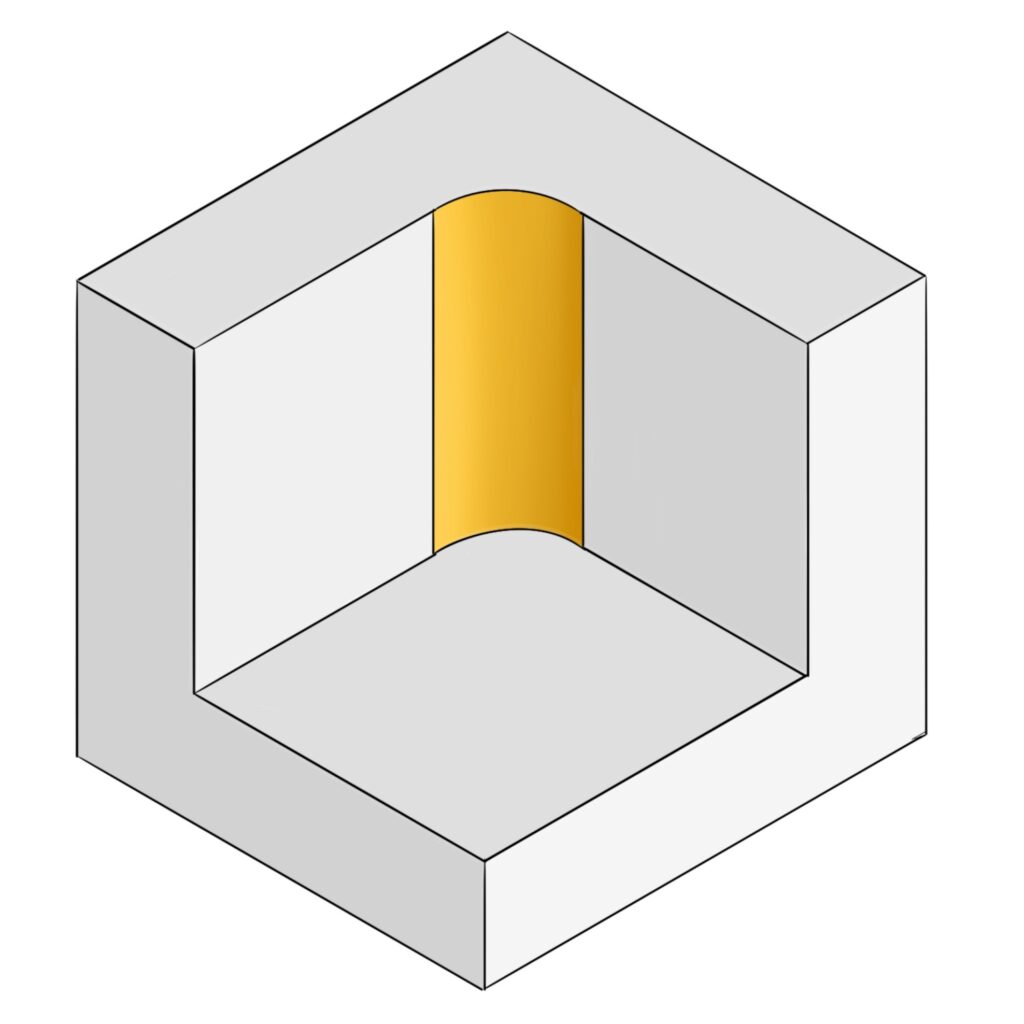

INSTApart machines and finishes your pockets and outline automatically, with sharp inner edges radiused.

For lowest costs, we recommend a minimum inner radius of 3.25 mm.

Minimum inner radius: 0.75 mm for parts up to 10 mm thick, 1.6 mm for parts up to 20 mm thick.

INSTApart can mill holes with optimal cost efficiency using the following diameters: 1, 1.5, 2, 2.8, 3.8, 4.2, 4.8, or 6 mm. Other diameters are predrilled and then milled to the specified size.

Minimum hole diameter: 1.25 mm for part thickness up to 5 mm, 2.25 mm for part thickness up to 10 mm, and 3.25 mm for part thickness up to 15 mm.

We also offer precise fits of 3H9, 4H9, 5H9, 6H9, and H10 for other diameters in out Web Tool.

INSTApart offers thread milling through our web calculator. We can mill threads from M2 to M12 to the following depths:

Please don’t upload modeled threads from Fusion 360 as these are not supported at the moment. You can deselect them for Step export.

We do not recommend placing text on your workpiece as we lack a text recognition algorithm. Text below the minimum feature size will be ignored.

Minimum feature size: 1.25 mm for parts up to 10 mm thick, 3.25 mm for parts up to 20 mm thick.

INSTApart is fully capable of milling chamfers and fillets. However keep in mind that we usually approximate chamfers and fillets with a small step over. Thus increasing production time and part cost.

We recommend omitting chamfers and fillets if they are not necessary as we automatically deburr parts using an electrochemical etching process.

We recommend a minimum wall thickness of 1 mm to avoid instability during manufacturing.

INSTApart automatically deburrs aluminum parts using an electrochemical etching process. Slight surface discolorations are normal, and while the process usually deburrs the entire part, minor burrs may remain.

Plastic and carbon parts are cleaned but may still have slight burrs or sharp edges.

We do not offer separate surface finishes at the moment.